NDT Inspection Plugs

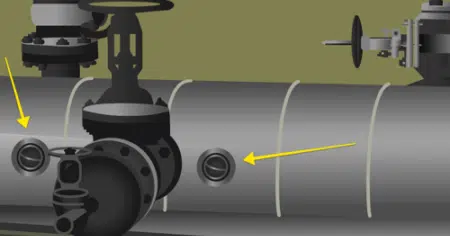

Specified Nondestructive Testing (NDT) Inspection Plugs monitor Corrosion under Insulation (CUI) and mechanical integrity.

NDT Inspection plugs access insulated pipe, pipeline equipment, storage tanks, pressure vessels and pipelines for petrochemical, oil and gas, steam and nuclear power generation.

Removable inspection plugs (install once) allow repeat access to monitor testing points for various NDT/NDE procedures.

Engineered / Specified for EPA/OSHA access of Mechanical Integrity management requirements.

Inspection Plugs seal the access testing points with Aluminum or Stainless Steel metal cap.

EPDM sleeve, metal handle w/lanyard and locking ring are standard and:

- Protect against Corrosion Under Insulation (CUI)

- Chemical and UV Exposure Protection, Ozone and Weather Resistant

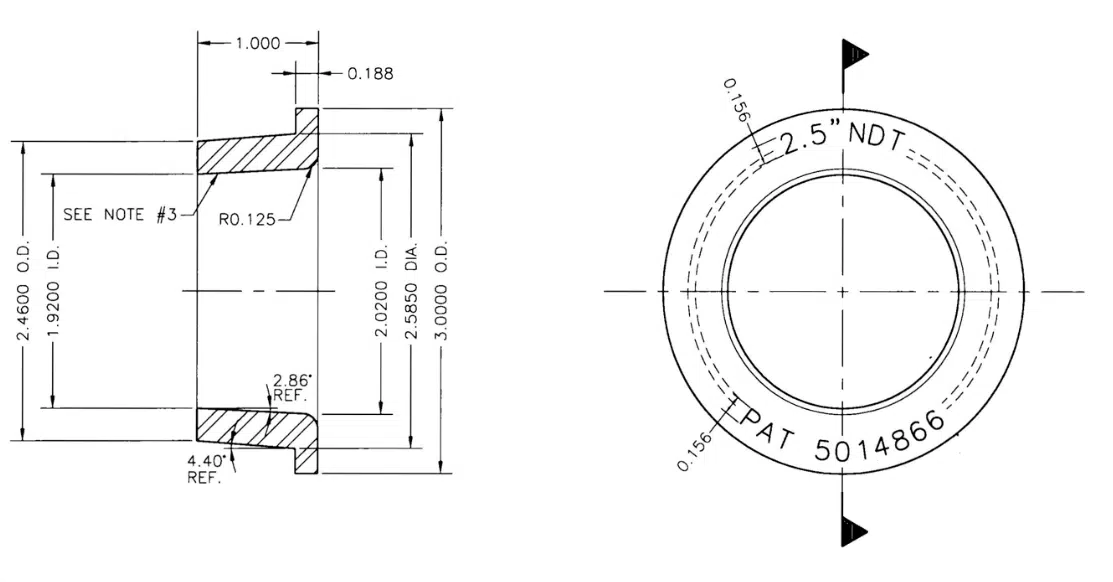

NDT Plug Sizes as Diameters:

1.5″ | 2.5″ | 3.0″ | 5.0″

(38, 64, 76, 127 mm)

Inspection Plugs can be installed on smooth or corrugated insulated jacketing.

Aluminum and Stainless Steel plugs ship standard w/EPDM sleeves, locking ring and lanyard to create an insulated seal.

NDT Plug Installation

Locate and mark the insulation jacket where the inspection plug will be installed:

- Hole saws are best to penetrate the insulation jacket, cut a circumference equal to the plug to be installed.

- Use either tin snips or a holesaw to penetrate the insulation jacket with a diameter equal to the size of the Inspection Plug.

- Remove the insulation to expose the substrate for inspection.

- After inspection, re-insert the insulation or replace it with a high-density material.

- Insert the EPDM or Silicone Sleeve.

- Install the Inspection Plug Locking Ring and Lanyard if equipped.

- Insert the metal cap to create a seal

Note: Caulking around sleeve for cold weather applications recommended

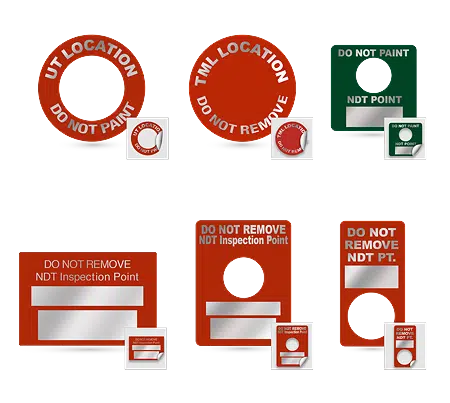

TML / UT Inspection

Point Labels

Test Measurement Location (TML) +

Ultrasonic Testing (UT) Inspection Point Labels

Inspection Point Labels to

ID and locate testing access points.

250) labels per roll.

Note: Acrylic adhesives require 48-72 hours to achieve 90% of its ultimate bond strength for best performance.

Inspection Point Labels

- Clean and dry the application surface for maximum bond strength.

- The surface should also be free of loose particulates, such as dust, dirt, and corrosion.

Note: Acrylic adhesive requires 48-72 hours to achieve 90% of its ultimate bond strength.

NDTspek has been an Online Distributor

of NDT Inspection Plugs + Labels since 2010.

Part of Great Northern Products, Inc.

In business since 1996.